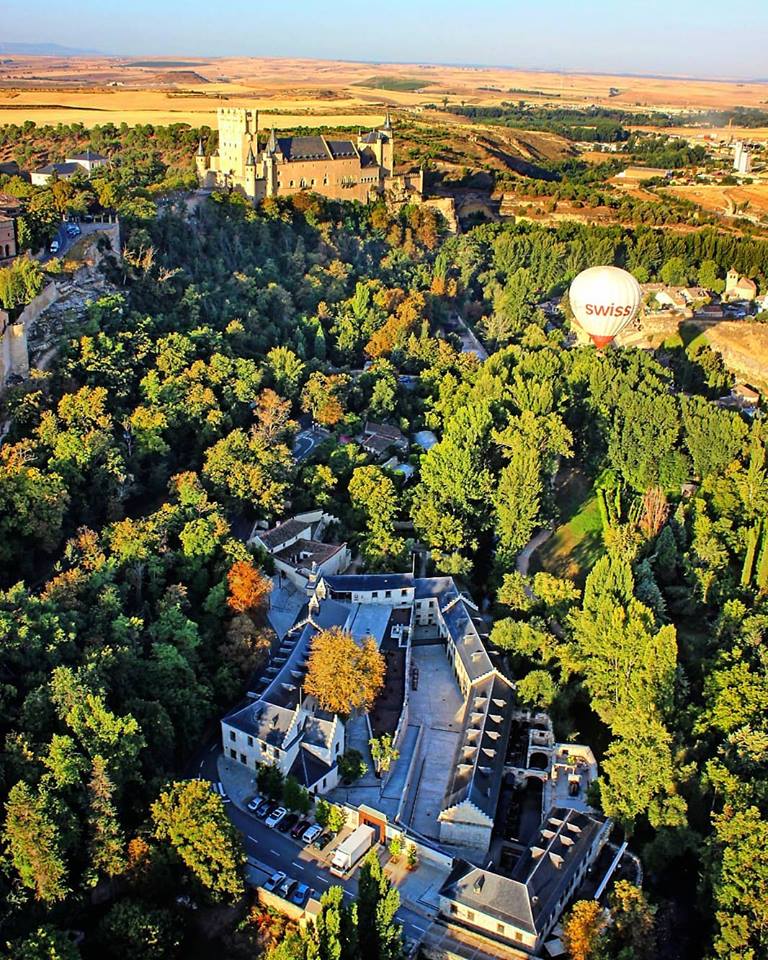

Segovia was chosen by Philip II to build the Royal Mint between 1583 and 1588, after considering and rejecting cities such as Madrid, Seville, Toledo and Lisbon amongst others.

The building is the best preserved example of industrial heritage in Spain and one of the oldest mints in the world. It was the first in Spain to produce mechanised coins, which represented a revolutionary change in the history of minting, making the production of coins more concise and efficient.

The mint, known as the “Real Ingenio de Segovia” (“Royal Engineering Mill of Segovia”), was designed not only to install the most modern machinery of the time, but also to house the different departments involved in the industrial process.

The new system allowed mass production and, for almost two hundred years, it was one of the most modern mints in Europe. Philip II would have been able to mint coins more efficiently here, using mills that were powered by hydraulic force.

The design of this avant-garde mint was the work of Juan de Herrera, one of the most influential and important architects in the history of Spain, who carried it out in collaboration with Austrian technicians. The factory was designed to carry out the entire minting process, from the arrival of the raw metal to the finished coin.

The initial minting system was replaced in 1771 by the flywheel press. This was introduced into Spain from France by the Bourbons.

The third and last minting system used was the automatic press. This system operated in Segovia for only three years because, in early 1869, coin production was centralised at the mint in Madrid.